Sodium Silimor Mortar

Sodium Silicate Mortar is widely used for Acid Resistant Bricks & Tiles lining works as Bedding & Jointing Mortar for Tanks, Floor, Drain, Foundation etc.

Resistant to:

- Sodium Silicate mortar are useful in PH range of 0-6 except where sulphuric acid exporser existing in the vaper phase wet-dry exposures or in concentration above 93% It is also resistant to Oxidizing & Non-oxidizing Acids, & except Hydrofluoric Acid & Water.

Resistant to temperature :

- 1000° C (Max.)

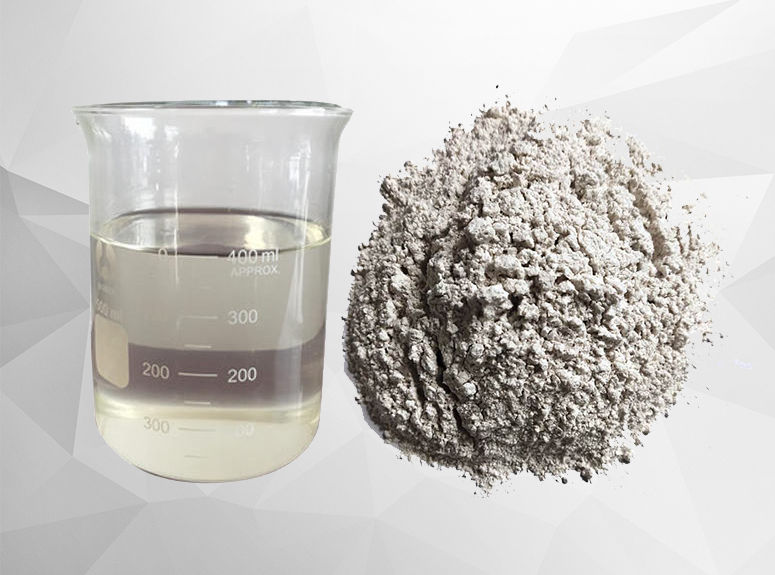

Preparation of Mortars:

- Preparation of Mortar generally consists of Solution & Powder. In order to obtain good working consistency, the average mixing ratio is 1 Pbw of Solution & 3 pbw of Powder. This ratio will slightly vary depending upon the temperature and working conditions.

- Prepare small batches of Mortar. Stirrer the Solution thoroughly before use. Place the Solution in a suitable mixing pan and add powder in it. Mix thoroughly with a spatula or Trowel. The mixing operation shall be continued until a uniform mixture is obtained.

- Make sure that all the Mortar is used from the mixing pan before another batch is prepared.

Surface Preparation:

- The cement plastered surface shall be slightly rough in line & level , dry & clean, free from dust, dirt, grease, oil etc., maintaining required slope etc. as no slope can be adjusted or altered in Acid proof lining works.

Setting / Curing :

- Silimor Resin Mortar is a Self-hardening due to its chemical reaction which occurs when the Powder & Resin are mixed together.

- An initial setting occurs in 6 to 8 hrs. at 30°C

- Final Setting occurs in 24 to 48 hrs. at 30°C

- Curing time: 7 days at °C

- Please ensure that no water shall be spilled over the bricks lining works before it completely cured.

Sodium silimor mortar cond.. (Acid Resistant Mortar)

Acid Curing:

When the bedding & jointing mortar is different, after the bedding mortar is properly set, cure the joints for a minimum period of 72 hours with 20 to 25% HCL acid before applying the resin type mortar. After acid curing, wash the free acid in the joints with clean water & allow sufficient time for thorough drying. Resin mortar shall then be filled into the joints.

Mechanical/physical property

- Working time at 30°C : 15 minute (min)

- Density of cured mortar : 2 grm per cc

- Bond strength : 5 Kg.Cm2

- Compressive Strength : 100 Kg/Cm2

- Flexural Strength : 35 Kg/Cm2

- Toluene Absorption : Max. 18%

Storage Life

- Solution : 24 Months at the temperature 30°C (+2°C)

- Solution : 24 Months at the temperature 30°C (+2°C)

All two components are stored in cool and dry place under the roof until ready to use it original unopened (Sealed) containers.

Packing:

- Solution : 75 Kg. in M.S. Drum

- Powder : 50 Kg. in Plastic Bag.

Export Packing:

- (As per customer’s requirement)